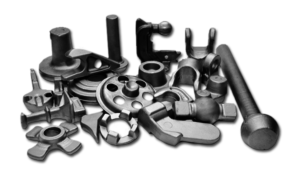

We are pleased to offer you cooperation in the production of die forgings, stamped elements and link chains as well as the processing of these elements into finished products.

Thanks to a wide range of production possibilities and many years of experience, we are able to adjust our offer, taking into account the optimal method of forging (hammer, press, forging machine, etc.) or an appropriate alternative type of input material. and thus offer products at very attractive prices. The forgings we produce are mainly used in the agricultural, machine, railway, mining, energy and automotive industries. shipbuilding, construction and power hydraulics industries. The overall dimensions of products produced by us range from 0.20 kg to 300.0 kg, diameters to 500 mm max and length to 1500 mm. An additional benefit allowing to reduce costs are our automated heat treatment lines where standardisation processes and quench hardening are carried out. It is possible for us to make finished forgings, i.e. with mechanical processing such as turning, milling, drilling, as well as painting and galvanizing.

Due to the increasingly frequent requests for forgings in small quantities, we have introduced open-die forgings to our

offer. Open-die forging is used in small-lot production and for large-size products, when fabrication of dies is unprofitable. Free-forging processes are

also applied to obtain a product with better strength parameters than casting or rolling. We offer forgings of rings, discs, cubes, shafts, bars of various

cross-sectional shapes, etc. weighing up to 5000 kg. This technology gives us the opportunity to offer you even one item. We offer our regular clients

the possibility of fulfilling orders according to the delivery schedule. After receiving the planned delivery dates, the production is prepared in advance.

This allows us to sell from our warehouse. Such a system guarantees our customers on-time delivery, and therefore it doesn’t cause any delays in

their own further production.

The main goal of our company is to provide the customers with a wide range of products at affordable prices. Customer

satisfaction and meeting all their requirements is the priority goal of FERUS.

We invite you to cooperate with our company.